The current version of the Tecniplast website doesn't match your region. Please visit your local website to find information and offerings specific to your country.

The current version of the Tecniplast website doesn't match your region. Please visit your local website to find information and offerings specific to your country.

Major international standards for Biological Safety Cabinets (BSCs) - Proper Selection, installation and safe use of certified BSCs. Main differences and essential elements for regular servicing, certification and preventive maintenance of Class II BSCs.

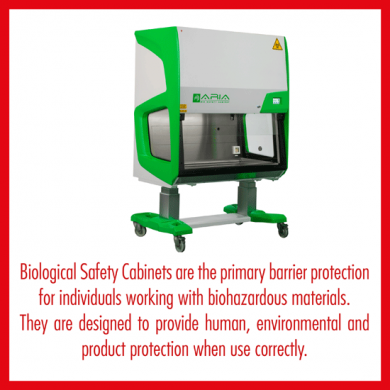

As we know, Biological Safety Cabinets (BSCs) are the primary barrier protection for individuals working with biohazardous materials. They are designed to provide human, environmental and product protection when use correctly.

Three types of biosafety cabinets, classified as Class I, II and III, have been developed to suit various research and clinical needs depending on level of protection required.

BSCs should not be confused with a Laminar Flow Hood that only protect the material being worked with and are not suitable for work with infectious or toxic material.

For the above-mentioned reasons, BSCs must be:

This will ensure that the research unit adheres to all international standards to be as effective as possible.

The poster in question features on Class II BSC (Class II A2 as per NSF49), which is the most commonly used cabinet due to its unique feature of laminar down-flow air which guarantees an animal / sample protection while being handled in the cabinet from potential contamination.

The key differences between the major international standards on Class II BSCs (AS 2252; EN12469; NSF49) are as follows:

The information presented is unbiased and generic in nature compiled with help from international regulations, experienced engineers and safety enclosure users.