This is Tecniplast Frequently Asked Question list (FAQ). It attempts to answer some of the most frequently asked questions related to Tecniplast and IWT products.

If you do not find an answer to your questions, please contact us at tecnicom@tecniplast.it and we will respond as quickly as possible.

The question is legitimate for any and each IVC system by at least two considerations:

Individually Ventilated Cages are closed containment devices separating small group of animals also in terms of incoming air. HEPA filtered air is pushed in each cage creating a local barrier.

Procedures in use for handling the animals are carried under strict protective conditions for both animals and operators. Thus, a decreased risk of cross-contamination between cages occur.

It is important to remember that the two conditions mentioned above are also responsible for the extremely low risk of microbiological contamination of animals maintained in IVC.

It is a matter of fact that primarily airborne transmitted microorganisms have very few chances to be transferred from one IVC cage to the other.

In a situation like the one described is crucial to identify the structure of the “animal unit”, in other words the definition of the cage groups/animals with at least a common risk factor: i.e. the same air distributed to that group of cages.

If we follow this approach all cages connected to the same air handling unit can be considered our “microbiological unit” to be tested by means of sentinel animals.

And one or more sentinel cages will be the “health monitoring tool” for that group of animals.

A detailed practical description for an health monitoring plan will be given in a second section of the answer.

One of the methods for health monitoring in IVCs using the traditional sentinels system is to consider each rack connected to a ventilating unit a “sub-unit” to be monitored in our facilities.

In this way each rack has at least one cage (number 1) with a number of sentinels receiving on a weekly or any other week basis, some dirty bedding (may be water as well) from a defined number of cages in that rack.

Sentinel rodents will be treated this way for twelve weeks and after this period another sentinel cage (number 2) is allocated on the rack undergoing the same process. The rodents in the sentinel cage number one are not sent for health screening prior than 4 weeks to allow the development of antibodies in case of contamination.

Each rack can be monitored every 3 months, but is also possible to approach the schedule for the screening in a different way.

An example is to consider and define some categories of interest: the annual pathogens (those less common), the common pathogens and the special pathogens.

Eventually each room will have a variable number of sentinel cages that will allow multiple monitoring over the time of the sanitary condition.

The choice of sentinel cages in terms of strain and stocks can be done in a flexible way having in each sentinel cage different strains may be the same maintained on that specific rack. A good idea is always to have a sentinel cage with nude mice in addition to the standard sentinel group for accurate and reliable microbiology, bacteriology and hystopathology.

A working group was recently set up in Europe in order to decide on the Standard Evaluation Criteria for IVCs.

The criteria are available on the Web and all cage manufactures have to comply with them.

Among other factors, it was agreed that air speed is an important parameter which might affect animal welfare.

The working group decided that the maximum air speed limit at animal level is 0.2 m/sec .

At 0.2 m/sec humans perceive the air draft so the assumption is the animals will do the same.

That is very critical especially with immunodeficient mice such as skid mice which could suffer from dehydration if the air speed exceeds 0.2 m/sec.

Tecniplast has designed IVCs featuring the air supply in the plastic top with the aim of conveying the air gently down to animal level guaranteeing an optimal microenvironment for animal welfare, keeping the bedding dry and allowing customers to carry out a bedding change only every 2 weeks.

In the guidelines, especially in the FELASA recommendations, the topic of environmental enrichment is extensively explored.

It is extremely important for the welfare of the animals to give them a proper environment in order for them to show normal behaviour, especially during breeding when mother and litter share the same space.

That’s why the design of a cage is very important and has to follow specific rules to provide the occupants with a proper floor area and the right internal height and thus avoid causing distress to the animals.

Tecniplast designs its cage equipment through dedicated working groups of animal laboratory experts who give us the proper input in order to develop the appropriate cage environment to address the welfare of rodent species as well as the relevant enrichment designed to avoid abnormal behaviours.

Tecniplast developed the Mouse House which is a red tinted transparent polycarbonate enrichment device which gives mice a way to squeeze, jump, climb, mark their territory and display their normal behaviour, in addition to offering a place to hide while still allowing the animal care takers to see inside.

Tecniplast has also designed the Mouse Loft for their Green Line IVC cage with auto-watering.

The Mouse Loft offers an internal raised shelf for the animal to climb, jump and explore the environment in 3 dimensions .

3D space is especially important for rats which like to stand up on their hind legs in a bi-pedal posture.

When a big rat of more than 600 g stretches up, its height can even exceed 30 cm.

Tecniplast has developed its new IVC rat cage called Double Decker on 2 floors in order to address that specific need.

It is a 1800 cm2 cage distributed on two floors:

A floor base of 1000 cm2 and an upper deck of 800+ cm2.

The upper deck allows the animal to stretch, jump and climb, showing their normal behaviour when group housed or during breeding studies.

Tecniplast conceives its air handling units with the following characteristics in mind:

- Multi-rack linking

- Ergonomics

- Low noise emission

- No vibration transmitted to the animals

The air handling unit is a stand alone trolley easy to roll in and out of the animal holding rooms with twin fan supply and exhaust modules which are able to ventilate at 75 ACH. up to 4 single or two double sided racks.

Tecniplast opted to have the blower as a stand-alone trolley in order not to have to install it on top of the racks.

That makes them ergonomically easy handle during routine maintenance or movement for sanitization.

Moreover, being stand alone it offers very simple access to pre-filters and HEPA filters.

This is a well known problem which occurs when customers autoclave cages in a double-wrapped knotted NON suitable plastic bags.

The common perception is that when there is the need to autoclave cages biohazard plastic bags have to be used.

Such bagse are extremely resistant but they offer the following disadvantages in autoclaving cages:

- They do not allow steam to penetrate inside the bag.

- When wrapped and knotted some air is trapped inside.

The problem is that the plastic bags thus close with air inside work as “balloons” in the autoclave.

During the vacuum phase of autoclaving the air inside the “balloons” exerts tremendous pressure on the plastic cages stacked inside, causing them to implode.

To avoid this problem it is advisable not to use standard biohazard bags but to buy suitable bags for autoclaving the cages.

The best bags for this purpose are normally of the three-ply type (polypropylene, polyamide, polypropylene) with a long filter.

The filter is the key feature because it allows the air inside the bag to escape during vacuum phase in autoclaving and the steam to penetrate inside the bag in order to sterilize the cage.

Although considered autoclavable, Noryl parts will gradually weaken and change colour after repeated autoclaving. Therefore, we recommend autoclaving Noryl parts only when absolutely necessary.

If cages are washed prior autoclaving, it is important to be certain there are no detergent and rinse aid residues on the surface to prevent the residue from baking on, causing change in colour or even chemical damage.

The difference between Polycarbonate and Polymethylpentene is that PC is a material with strong mechanical but weak chemical resistance. The upper chamber with lid, the lower chamber with closure, the water bottle and the feed drawer are made of Polycarbonate. It is autoclavable up to 121° C.

PMP, on the other hand, is a material with strong chemical but weak mechanical resistance. The collection funnel, the separating cone, the urine collection ring and the two collection tubes are made of Polymethylpentene (PMP). It is autoclavable up to 134° C.

It is important to follow the procedures here below:

- DO NOT stack PMP parts when autoclaving them.

- DO NOT autoclave cage components on their edges. Autoclave all the components in an upright position and let them cool down on a level surface.

- DO NOT exceed the suggested autoclaving temperature.

- Autoclave PC parts only when strictly necessary. PC parts may gradually weaken or be damaged after repeated autoclaving (warping, clouding, cracking).

- Avoid thermal pulsing cycles.

- Before autoclaving ensure that no detergent residues are left on the cage.

Before starting metabolism tests it is important to let the animal acclimatize on the grid for at least 48 hours. It is necessary to get the animals used to powder food as well.

In catalogue one, you can find the raised bottom grid and powder feeders to acclimatize the animal in its standard cage.

If mice and rats do not become gradually accustomed to the new environment, they may risk losing weight (not eating), dehydration (not drinking), dysfunctional behavior (stress signs) and the death of the animal in the worst scenario.

Not if used properly. Tests were run on a HEPA filter backed up with a charcoal filter, exposing the unit to 100 micrograms per litre of DOP for two hours. NO DOP penetration could be detected. Clean air was blown through the system for another hour and then the charcoal was analyzed for traces of DOP. The result was zero.

The DOP particles, being a liquid aerosol, impinge on the surfaces of the glass fibres making up the filter, and are trapped there. Each tiny droplet spreads out to form a mono-molecular layer on the surface, and since the surface area is extremely large, there is little chance of saturation. it would take an extremely high concentration of DOP, generated very close to the filter surface, to cause wetting out. Once the DOP is trapped, it stays on the fibres and is not released.

There are nine classes of clean rooms specified in ISO 14644. These classifications are based upon particle counts within one cubic meter of room air. ISO Class 1 is the highest or cleanest rating. ISO Class 9 is the lowest possible rating.

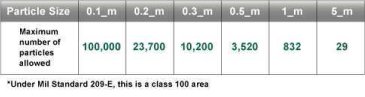

In a cage changing station working area the maintenance of ISO Class 5 air quality is required. Below are the particle count requirements for ISO Class 5*:

The ideal location is a dead-end corner of the laboratory, away from personnel traffic, vents, doors, windows and other sources of disruptive air currents.

A pit is not necessarily required.

You can provide a pit 70 mm deep (or 100 mm deep if the fogging option is fitted) where the decon lock is to be installed, ensuring that the bottom part of the door frame is flush with the building floor. When the pit is not provided, the machine can be installed on the existing floor and we can provide a ramp to make up the clearance between floor and door frame. It is good practice to provide a drain inside the pit even though the decon lock does not require it.

The decon lock equipped with H2O2 and/or ClO2 can work as a stand-alone unit, without the need of the exhaust ductwork.

With this configuration the filtration unit with the catalyser will decompose the decontamination agents. When you have also the fogging option you need to provide exhaust ductwork.

The rule is:

H2O2 no ductwork needed when you have the catalyser

ClO2 no ductwork needed when you have the catalyser

Fogging ductwork required

The catalyser breaks down H2O2 and ClO2 by absorbing oxygen. The catalyser is very sensitive to moisture.

Fogging, being water based, contains such a high quantity of moisture (H2O) that would be detrimental for the catalyser since it would become saturated in a very short time.

Yes, there is a distribution system. The gas injection point is positioned next to the diffuser, on the side wall, and the gasses, once delivered into the chamber, are gently wafted by the air stream generated by a fan and spread/distributed evenly to obtain a perfect coverage of the chamber as well as the load.

The cycle time is strictly related to the selected process, to the generator in use and to the load.

As far as H2O2 is concerned, the shortest cycle time we can guarantee, with a 6 log reduction, is 60 minutes.

First of all it has to be reiterated that the chamber is leak tight and the pressure inside the chamber is constantly monitored in order to make sure that no leaks occur. However, we can offer two types of gas monitoring sensors: a portable one, which is extremely accurate and very useful to assess the residual concentration inside the chamber at the end of the cycle via test points, and the room monitoring system to be installed next to the chamber in order to monitor the environment and warn the personnel in case of leaks.

Aquatics Systems are divided into two lines, the ZebTEC and the XenopLus;

Below is the list of dimensions and weights.

ZebTEC systems: ZB1020B1000MN

Standard configuration overall dimensions 1759(W) x 587(D) x 1078(H) mm.

Net weight: 130 kg; Operating weight: 294 kg (varies according to tank configuration);

Weight per each system foot: ~55kg (varies according to tank configuration).

ZB2550B1000SASX & ZB2550B1000SADX

Standard configuration overall dimensions 1667(W) x 555(D) x 2107(H) mm.

Net weight: 220 kg; Operating weight: Max 500 kg (varies according to tank configuration);

Weight per each system foot: Rack ~85kg (varies according to tank configuration); WTU~40kg.

ZB2550B1000SAREM

Standard configuration overall dimensions:

Stand Alone dimensions: 1370(W) x 555(D) x 2107(H)mm.

Electrical box dimensions:400(W) x 200(D) x 500(H)mm.

Dosing tank dimensions:180(W9 x 200(D) x 500(H)mm.

Net weight: 220 kg; Operating weight: Max 500 kg (varies according to tank configuration);

Weight per each system foot: Rack ~85kg (varies according to tank configuration); WTU~40kg.

ZB2550B1000SX & ZB2550B1000DX

Standard configuration overall dimensions 16671374(W) x 419(D) x 2103(H) mm.

Net weight: 200 kg; Operating weight: Max 400 kg (varies according to tank configuration);

Weight per each system foot: Rack ~70kg (varies according to tank configuration); Sump~30kg.

ZBWTU001R & ZBWTU001

Standard configuration overall dimensions 1005 (W) x 900 (D) x 2006 (H) mm.

Net weight: 290 kg; Operating weight: 580 kg;

Weight per each system foot: 145kg.

XenopLus systems:XP09B100SACP & XP09B100SARCP

Standard configuration overall dimensions 1816 (W) x 806 (D) x 1914 (H)mm.

Net weight: 300 kg; Operating weight: 650 kg (varies according to tank configuration);

Weight per each system foot: Rack ~122,5kg; WTU~40kg.

XPF12B100SACP & XPF12B100SARCP

Standard configuration overall dimensions 1816 (W) x 681 (D) x 1914 (H)mm.

Net weight: 300 kg; Operating weight: 570 kg (varies according to tank configuration);

Weight per each system foot: Rack ~102kg; WTU~40kg.

XP09B100CP

Standard configuration overall dimensions 618 (w) x 1665 (l) x 1914 (h) mm.

Net weight: 210 kg; Operating weight: 450 kg(varies according to tank configuration);

Weight per each system foot: Rack ~112,5kg.

XPF12B100CP

Standard configuration overall dimensions 618 (w) x 1665 (l) x 1914 (h) mm.

Net weight: 210 kg; Operating weight: 370 kg (varies according to tank configuration);

Weight per each system foot: Rack ~92,5kg.

XPWTU001R & XPWTU001

Standard configuration overall dimensions 1005 (W) x 900 (D) x 2006 (H) mm.

Net weight: 290 kg; Operating weight: 500 kg;

Weight per each system foot: 125kg.

Environmental parameters may have side effects on Aquatic systems.

Essentially the main parameters to be kept under control are:

- Room Temperature.

- Room Ventilation.

- Light Intensity/positioning and Circadian light cycle.

Room temperature directly influences water parameters, such as temperature and pH (pH especially, increasing or decreasing on a logarithmic scale, can vary a lot with even a slight temperature variation). Heat is exchanged from the tank to the air and vice versa thanks to a physical phenomenon called “irradiation”; In case of room temperature higher than water temperature, this can cause water temperature to rise over the set point value and increase the water loss due to evaporation.

If the housing system is not equipped with a chilling unit (optional feature available on all systems), there is no possibility to directly correct water temperature back to the desired set point, the only way to do so is by adjusting the air temperature.

A different situation occurs when room temperature is lower than housing water temperature; in this case the system, equipped with heaters, is able to raise the value to the desired set point.

Tecniplast suggests a room temperature of about 2-3°C (~2°F) less than housing water temperature for the ZebTEC systems and ±1°C (~1°F) less than housing water temperature for XenopLus systems.

Room ventilation is extremely important in order to prevent water condensation on the walls and floor of the facility and to ensure a safe and healthy working environment for the animal care takers/technicians.

Water condensation can cause mould proliferation.

Tecniplast suggests 10÷12 air changes per hour (anyhow, never less than 6).

Light intensity should be at an adequate value in order to ensure animal wellness and to prevent algae formation.

Lights should be positioned above the fish tanks

Tecniplast suggests a light intensity of about 50÷350 Lux at water surface and a circadian light cycle of:

14 hours light followed by 10 hours dark or 12 hours light followed by 12 hours dark.

The spawning of zebrafish is induced by the light cycle set in the room. When the lights turn on, within about half an hour the fish will generally have spawned.

The Bio-filter is a living entity and can be considered as the real heart of a recirculating system.

It is needed to reduce the concentration of the toxic part of the Nitrogen compounds in solution in the water.

Nitrogen is an essential nutrient for all living organisms and is found in proteins, nucleic acids, adenosine phosphates, pyridine nucleotides and pigments.

In the aquatic environment, nitrogen is of primary concern as a component of the waste products generated by rearing aquatic animals.

Fish expel various nitrogen waste products through gill diffusion, gill cation exchange, urine and feces.

The decomposition of these nitrogenous compounds is very important because of the toxicity of ammonia, nitrite and, in some cases, of nitrate.

The process that takes place in the bio-filter is called “Nitrogen cycle” or nitrification where safe bacteria (nitrifying bacteria) naturally perform the successive oxidation of ammonia to nitrite and finally to nitrate.

Ammonia is the principal nitrogenous waste as the major end-product of protein catabolism.

A second source of Ammonia comes from the so called “Mineralization” performed by Heterotrophic bacteria that reduce faecal matter and uneaten food into Ammonia.

More than 50% of the waste produced by fish/frogs is excreted as un-ionized ammonia.

Ammonia is a highly toxic compound even at low concentrations.

In water, ammonia exists in two forms: un-ionized (NH3) and ionized (NH4+) and is usually measured as TAN (Total Ammonia Nitrogen) in mg/l. or ppm.

TAN = NH3 + NH4+

The un-ionized form (UIA) is the toxic fraction.

The relative concentration of each of these forms of ammonia is mainly a function of pH and temperature.

An increase of pH and temperature increases the proportion of the un-ionized form of ammonia.

Ammonia toxicity is particularly problematic in newly established recirculation systems, overcrowded aquariums as well as in shipping containers.

Fish suffering from ammonia toxicity may exhibit behavioral abnormalities, such as hyper excitability, increased respiratory activity, oxygen uptake (gasping at the surface) and increased heart rate.

Even relatively short exposures can lead to skin, eye and gill damage.

High levels can also lead to ammonia poisoning by suppressing the physiological exchange through the gills with damage to the internal organs.

The fish response to high ammonia levels can include lethargy, loss of appetite, laying on the tank bottom with clamped fins, or gasping at the surface.

As a result, fish may experience a reduction in hatching success, reduction in growth rate, abnormal development and increased susceptibility to pathogens.

When levels of Ammonia rise, the Ammonia oxidizing bacteria (AOB), belonging to the genus Nitrosomonas, oxidize Ammonia into nitrite.

Nitrite is the intermediate product of the Nitrification process from Ammonia to nitrate.

Although it is usually converted to nitrate as quickly as it is produced, a lack of its biological oxidation can end in a high level of nitrite, potentially toxic to the animals.

Nitrite toxicity is the cause of the so-called “brown blood disease”, having a direct impact on the ability of blood hemoglobin to carry the oxygen.

When it enters the blood stream, nitrite oxides the iron in the hemoglobin from the ferrous to the ferric state.

The resulting molecule is called methemoglobin, which has now a characteristic brown color.

In conclusion, this results in hemoglobin incapable of combining with oxygen, thus hypoxia occurs.

Other N-bacteria belonging to the genus Nitrobacter (NOB – Nitrite oxidizing bacteria) oxidize nitrite into nitrate. Nitrate is the end product of nitrification and is the least toxic of the nitrogen compounds.

Excess of nitrate causes stress making a fish’s organs work harder to adjust to their environment.

The increasing stress results in the fish losing the ability to fight diseases, heal themselves and reproduce.

Ideally no more than 50ppm should be present but the lower the better.

But since nitrate is the result of the nitrification process, it will always be present.

The only way to reduce it is by periodically changing the water: that is why recirculation systems are commonly known as: “semi-closed recirculation systems”.

The N-compounds can be checked either by using “colorimetric testers” or with a photometer.

They should be checked daily (at least for the first 8 weeks of biofilter activation) and at least weekly once it is stable.

The advised levels for N-compounds are:

• Ammonia: 0.01 - 0.1 ppm

• Nitrites: < 0.2 ppm

• Nitrates: < 50 ppm

These values refer to a stable and mature biofilter.

Workplace Safety Exposure Limits vary according to the type of gas involved and are divided into:

- Long-term exposure limit (8-hours day or 40-hours x week Time Weighted Average abbreviated TWA as a reference period which people may be exposed to without adverse effects

- Short-term exposure limit (15-minute reference period)

Limits are expressed in PPM (parts per million) or in mg/m3

H2O2 Long term exposure 1 PPM - Short term Exposure 2 PPM

ClO2 Long term exposure 0.1 PPM - Short term Exposure 0.3 PPM

FORMALDEHYDE Long term exposure 2 PPM - Short term Exposure 2 PPM

ETHYLENE OXIDE Long term exposure 5 PPM - Short term Exposure NONE

For further information, please visit http://www.hse.gov.uk/coshh/table1.pdf

Efficacy of a decontamination cycle can be assessed by using BIs (Biological Indicators).

The most common BIs in use to validate decon cycles are Bacillus Atrophaeus and Geobacillus Stearothermophilus.

BIs are to be placed inside the chamber to monitor the coverage/distribution and on the load. After the cycle BIs are collected, planted in the appropriated culture broth and incubated for 14 days. A cycle can be considered acceptable when 100% of the BIs show no growth after the incubation period, meaning a 6 log reduction.

Each different load should be standardized and validated in order to optimize H2O2 consumption, cycle time and ensure repeatability over time. Nevertheless, in our chambers (either Rack Washer or Decontamination lock) a decontamination cycle using and average of 125 ml of liquid H2O2 (either 30% or 35% solution) can guarantee good results with a broad range of different loads.

When in doubt, it is always good practice to use Biological and/or chemical indicators to assess the efficacy.

The goods can be processed in both ways.

The decontamination cycle can be started from either side of the machines.

The exhaust ductwork is designed to convey gasses, moisture and vapours outside the building, via a chimney in order to ensure safe operation of the machine and a safe and comfortable working environment for the users.

IWT’s main requests for reliable, safe and durable ductwork are:

• made of stainless steel

• leak-tight

• dedicated and separate from any other duct

• properly sized and configured